2023-09-12

The bidirectional brother of the Bowden cable

Push/pull cables from RINGSPANN RCS prove their worth as currentless remote controls

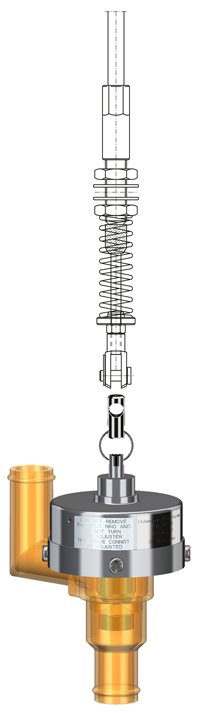

Push/pull cables from RINGSPANN RCS belong to the group of mechanical remote control systems and are used worldwide in almost all industries. Unlike traditional Bowden cables, they are bidirectional and can transmit both pulling and pushing forces and movements. These currentless remote actuators prove their worth in particular in safety-relevant applications that require a high level of functional reliability when triggering, locking, setting and operating.

Oberursel, September 2023. – Basically, push/pull cables from RINGSPANN RCS are flexible mechanical transmission elements that are characterized by high-quality workmanship, excellent sliding properties and long service lives. In their function as currentless, maintenance-free remote actuators, they are used in kinematic-constructive environments where two requirements meet: it must be possible to transmit both forces and movements in the direction of pressure and tension between two locations at a distance from each other. Traditional Bowden or wire rope hoists are ruled out for this purpose, as they only cover the aspects of pulling force and displacement. The cable systems from RINGSPANN RCS, on the other hand, prove to be extremely reliable operating elements under these conditions – not least thanks to their constancy of length. They meet high demands on accuracy and can also be laid in tight radii. In addition, there is another important reason for many machine, plant and vehicle manufacturers to use push/pull cables from the German manufacturer: "The premium quality of our remote actuators is one thing; however, it is at least as important that we can implement individually tailored cable systems for our customers that are precisely geared to their specific applications," says Frank Schneider, Sales Manager of RINGSPANN RCS.

Remote control systems for all branches

The company currently develops and manufactures its bidirectional operating and control cables – internationally referred to as mechanical remote control systems – for customers in almost all branches of industry. In conveyor technology, they are used in industrial trucks (e.g. speed control) or automatic storage and retrieval systems (e.g. safety gear); in e-mobility they are a functional component of loading devices or steering mechanisms; in vehicle construction they support the design of transmission gears and unlocking solutions; in marine technology they enable the implementation of modern SOS systems (e.g. lifeboat releases); and in railway technology – among other things – they are indispensable components of door, parking and emergency stop kinematics. Other major areas of application are aeronautical engineering (valve actuators, brake systems, etc.), machine tool construction (hold-down devices, etc.), medical technology (blood flow regulation, etc.), general plant engineering (interlocks, etc.), agricultural technology (regulatory systems, etc.), and many other industries.

Sophisticated precision solution

Based on its portfolio of standard cables, an impressive number of successfully implemented customer solutions and comprehensive engineering know-how, RINGSPANN RCS can offer one or more suitable push/pull or pull cables for almost every application. They are delivered ready for installation or assembly, can be supplemented with stainless tie rods and fasteners and have galvanized or stainless steel cables for power transmission that run in high-quality Bowden cable or push/pull jackets. "Technical highlights include coated push/pull inner cores in combination with flexible inner tubes, in which the core can slide smoothly. By using special sliding plastics, we can exclude the annoying stick-slip effect. In practical use, this ensures almost jerk-free, infinitely variable and very precise adjustment movements," explains Frank Schneider. With such quality features, the push/pull cables from RINGSPANN RCS score points, for example, in vehicle construction, marine applications, railway and aviation technology, as well as in numerous applications in general mechanical engineering. ar

In-house test bench secures know-how advantage

For about three years now, RINGSPANN RCS has had an in-house test bench, which expands the possibilities for further development and quality assurance of push/pull cables. This is a system solution designed exclusively for the company, the implementation of which took into account numerous demanding test scenarios that go far beyond the usual procedures. In this way, not only standard tests can be run, but also special force tests, friction measurements, cycle tests and idle stroke measurements, as well as routines for evaluating elastic elongation and much more. In addition to testing individual kinematic-dynamic performance parameters, the new system can be used to carry out sophisticated long-term test series and complex multiple-factor analyses, in which several different requirements are tested alternately. It can also be used in benchmarking projects.