2022-11-18

Strong precision solutions for heavy-duty drives

True Centering clamping sets from RINGSPANN score with extreme centering accuracy

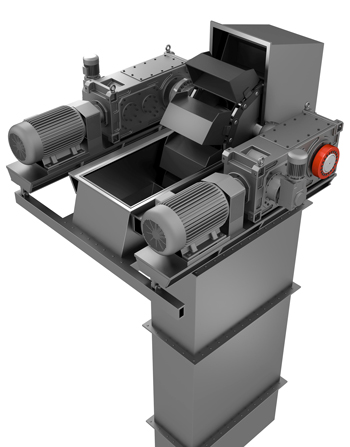

Cone clamping elements and shrink discs from RINGSPANN belong to the top group of friction-type shaft-hub-connections. Worldwide, they ensure safe and loss-free power transmission in the drive trains of conveyor systems, construction machinery, pumps, turbines and generators. The True Centering clamping sets and shrink discs of the RLK family are particularly suitable for use in earthmoving and bulk material installations in the coal and steel and mining industries. Read here to discover what distinguishes these machine elements.

Bad Homburg, November 2022. – As indispensable functional elements of friction-type power transmission, shaft-hub-connections from RINGSPANN can now be found in countless drive systems in international mechanical and plant engineering. The company's True Centering clamping sets and RLK shrink discs set standards in heavy-duty applications in coal and steel, mining and power plant engineering. They are characterised by extreme accuracy in hub-shaft centering and impress with their high transmittable torques. “In addition, they can always be optimally adapted to the customer’s drive peripherals – for example, if only low surface pressures are possible because the hubs are very thin-walled or because other connection parts have to be protected”, says RINGSPANN Product Manager Marvin Raquet.

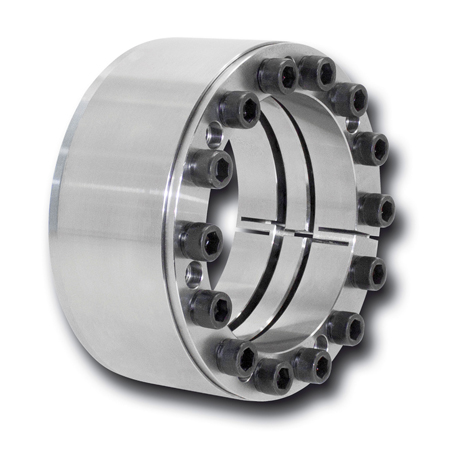

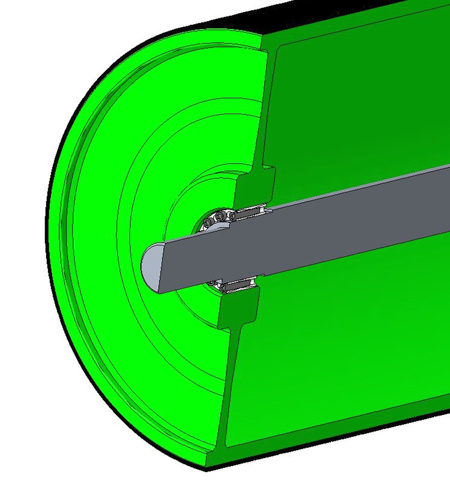

Exact fit thanks to double slot

The True Centering clamping sets RLK 402 TC und RLK 404 TC from RINGSPANN are internal clamping connections for backlash free fastening of hubs on shafts and are primarily used in the drive systems of bulk material conveying systems for coal and steel. Among other things, they are considered the optimal solution for applications with components that are exposed to increased bending stresses during operation – such as large conveyor belt drums. They score with excellent machining quality, transmit torques from 18,500 to 1,701,000 Nm and are suitable for drive shafts with diameters of 100 to 600 mm. In addition to their three-part design with particularly long and flat cones, a characteristic feature of the True Centering clamping sets from RINGSPANN is above all a double side slot of the inner and outer ring. “This double slot ensures extremely high accuracy when centering the hub on the shaft – even with multiple mounting; in addition, under normal requirements during clamping, axial displacement of the hub to the shaft is not to be expected,” explains Marvin Raquet. This means that a cone clamping element of the type RLK 402 TC or RLK 404 TC centres a belt drum on the drive shaft with the greatest precision, and drum and shaft remain positioned exactly in relation to each other. This means that the drive system designer does not have to consider potential inaccuracies in advance, nor do maintenance technicians have to worry about their maintenance work lacking precision. “Our RLK 402 TC and RLK 404 TC clamping sets make a direct contribution to safe and efficient plant operation and also support the reduction of MRO effort”, says Marvin Raquet.

“Upper performance limit”

The high performance of the two- and three-piece shrink discs in RINGSPANN’s RLK family is also based on the frictional locking principle. However, these are external tension connections for the backlash-free attachment of hollow shafts or hubs to drive shafts. They are used in mining and raw material extraction technology primarily in the gearboxes of bucket elevators, elevators or bucket wheel excavators. “With maximum transferable torques of 4,225,000 Nm, these shrink discs cover almost the entire range of coal and steel and power plant applications. At the same time, they currently mark the upper performance limit of our friction-type shaft-hub-connections in terms of power transmission,” explains Marvin Raquet.

RLK shrink discs from RINGSPANN are extremely easy to install and, depending on the variant, are suitable for shafts with a diameter of 14 to 620 mm. The company’s current bestsellers currently include the three-part shrink discs of the still relatively new RLK 603 S series. They score as versatile universalists for hollow shafts and hubs with outer diameters of 14 to 190 mm and transmit torques from 18 to 156,100 Nm.

By the way: thanks to its extensive engineering expertise and its high level of vertical integration, RINGSPANN is always in a position to make constructive modifications to its shaft-hub-connections or to implement customer-specific special solutions. “An example of this is the light version of our True Centering clamping sets, which today belong to the standard range, but were originally developed on behalf of customers for drive systems with mass-optimised lightweight hubs,” reports Marvin Raquet. ar

Internationally sought-after partner

Supported by its one-stop-shop strategy, RINGSPANN has positioned itself over the past few years as a global manufacturer of premium-class shaft-hub-connections. On the basis of its international presence and with five foreign production plants, the company is ideally positioned in this product segment both as a supplier and as a development partner for its customers. It is currently expanding the production capacities of its sites in South Africa, China and Europe.