2016-09-30

Packaging sausages on the high seas

New stainless steel RINGSPANN freewheels brave corrosion and acids

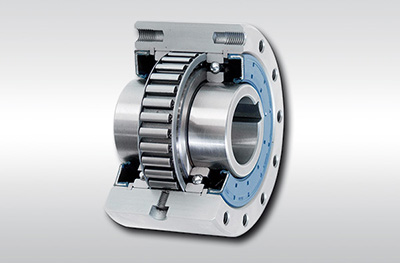

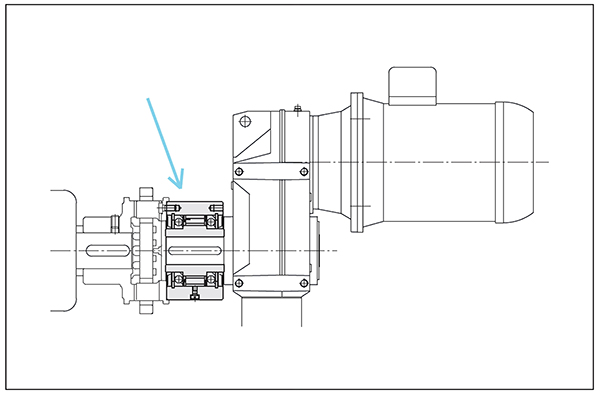

With its new FBS series freewheels, RINGSPANN not only makes life easier for manufacturers of food processing machines and packaging systems. The design engineers of seawater-resistant drive units for marine or offshore engineering also have reason to be pleased. For these high-performance complete freewheels for maximum torques of up to 10,000 Nm are made of stainless steel and are therefore extremely resistant to corrosion and chemicals. They can also be further optimised with food-safe lubricants and seals.

Bad Homburg, September 2016. – “You can even build them into sausage packaging systems for offshore operation if you need to”, says Thomas Heubach with a chuckle. What the director of RINGSPANN’s freewheels division highlights with this humorous comparison are the special areas of application of the new freewheel series FBS. For these high-performance complete freewheels have been especially developed for use in the drive systems of machines and systems for the production and packaging of foodstuffs. They are also outstandingly well-suited for applications in marine, offshore and chemical engineering. The main reason being: RINGSPANN manufactures this new FBS series from a special stainless steel defined and specified in close cooperation with renowned technological leaders in materials engineering. “These freewheels are therefore resistant to corrosion and acids – including nitric acid, which is frequently contained in cleaners and fertilisers”, underlines Thomas Heubach.

Use for clean room drives also on the cards

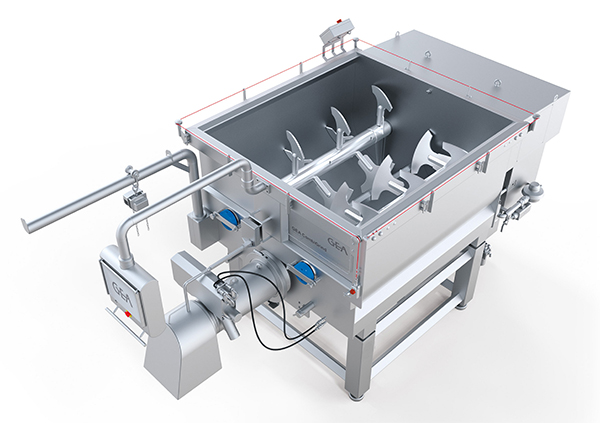

The stainless freewheels by RINGSPANN are already in use in different food engineering machines. For example, they have been running for some weeks now in the belt conveyor drive of a freeze-drying unit for poultry and in a production line for sausages. Typical applications for the new FBS series also include the production of meat mincing and dough processing machines as well as salad packaging lines and beverage filling systems. “Drive systems required to run under special clean room conditions are currently being discussed as a further area of application”, divisional manager Thomas Heubach adds.

Nine sizes in four variants

The stainless FBS freewheels by RINGSPANN can, depending on the variant, be built into the drive units as indexing freewheels, overrunning freewheels or backstops and are designed for maximum torques of up to 10,000 Nm. It is also interesting to take a second look at the altogether four FBS variants on offer. For, alongside a standard version for universal use, RINGSPANN offers three further application-specific variants for increased service life and precision requirements. “Whilst the sprags of the RIDUVIT® type FBS have a carbide-like wear-protection coating, those of FBS type X are designed for applications with a quick-turning inner ring and those of FBS type Z for applications with a quick-turning outer ring”, explains divisional manager Thomas Heubach.

Irrespectively of the variant, the stainless freewheels of the FBS series by RINGSPANN are available in nine sizes with bores of up to 75 mm. In addition, they can be further optimised with food-safe lubricants and sealing rings for particularly high requirements in food processing. In terms of their design, the new FBS complete freewheels are sealed sprag freewheels mounted on ball bearings. They are supplied filled with oil and ready to assemble for bolting to the face. Depending on the lubricant used, they deliver reliable service under ambient temperatures of -40° C to +50° C. Implementing customised special versions is no problem for RINGSPANN.