2021-06-24

New perspective thanks to optimised e-brake series

RINGSPANN is expanding the areas of application of its electromagnetic disc brakes

The one-stop supplier RINGSPANN has added several functions and features to the range of its EV/EH series electromagnetic disc brakes. These compact solutions for safely stopping, controlling and holding rotating axes and shafts are thus advancing into many areas of application that were previously thought to be the domains of pneumatic and hydraulic brake calipers. In particular, the innovations of the EV/EH series offer designers of drive systems for machine tools, assembly plants, amusement rides and even offshore facilities further options to increase performance and optimise use.

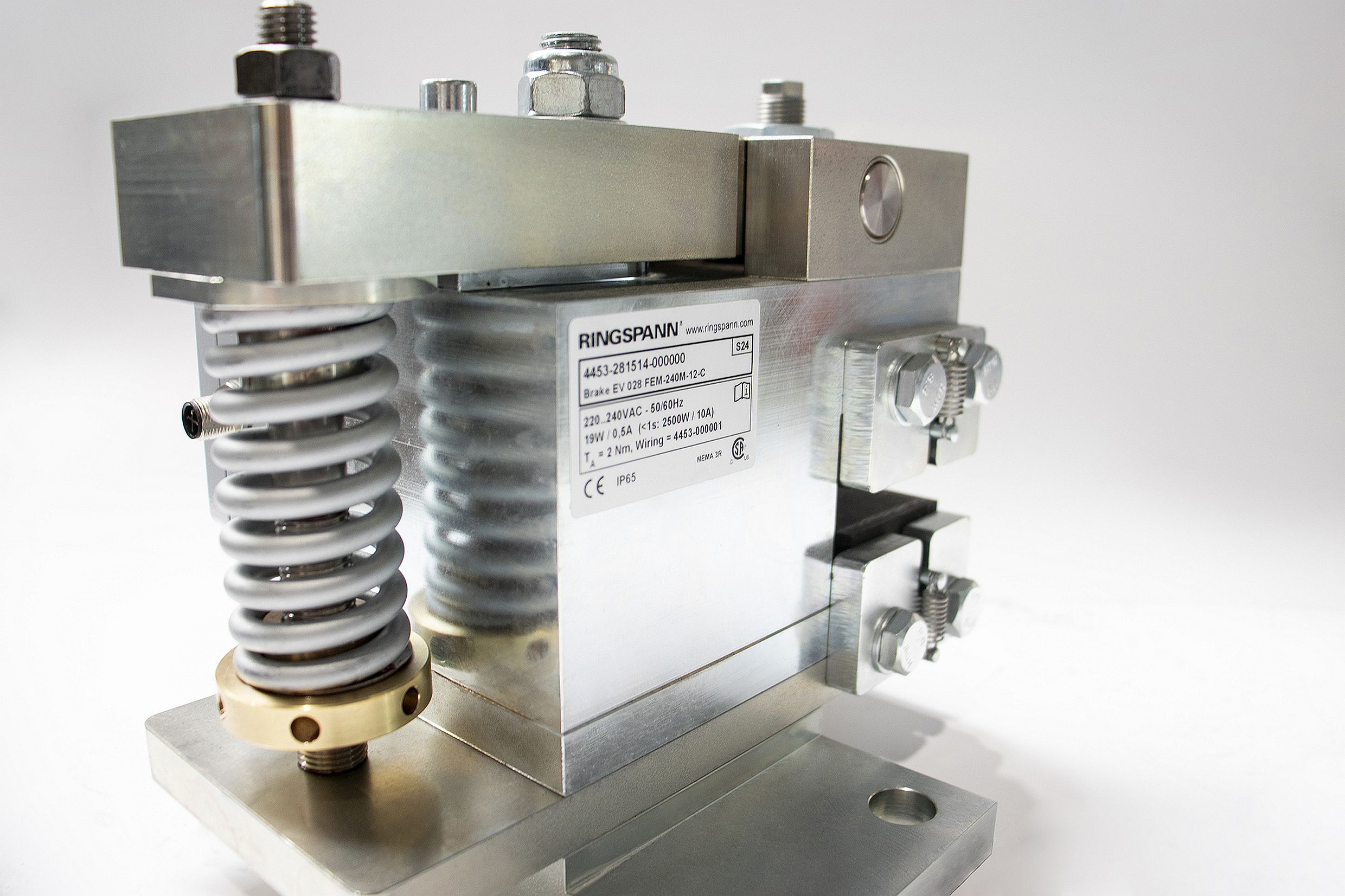

Bad Homburg, June 2021. – Many machine and plant manufacturers now rely on the use of electromagnetic disc brakes when implementing their drive systems. These electronically driven e-brakes convince both through functionality and energy efficiency, as well as with their compact size and low weight. It also provides a sensible alternative particularly for the producers who do not want to use hydraulic or pneumatic brake systems - not least due to the high installation and maintenance costs. In its dual role as a manufacturer and supplier of high-quality components for industrial drive technology, RINGSPANN was early to respond to this trend and added several electromagnetic disc brake series to its portfolio. The EV/EH series in particular has undergone dynamic transformation. It now consists of four basic sizes (018, 024, 028, 038) for parallel (V) or right-angled (H) mounting on standard brake discs with diameters ranging from 125 mm to 900 mm. All versions have manual wear adjustment and are available in two variants: FEM (spring activated and electromagnetically released) and EFM (electromagnetically activated and spring released). In recent weeks, the company’s engineers have now optimised and enhanced these e-brakes to such an extent that it is opening up a multitude of new perspectives for their use. "In implementing these detailed innovations, we have consistently been guided by the requirements of the market and the wishes of our customers. A number of users who have not yet considered using e-brakes now also stand to benefit," emphasises Franz Eisele, who heads the brakes and couplings division at RINGSPANN.

Flexibility in terms of operating voltage

The innovations and optimisations in RINGSPANN’s EV/EH series apply to both the internal electronics and electrical engineering of the electromagnetic brakes, as well as to the aspects of performance, service life and operation. The fact alone that the e-brakes can now be used for mains voltages up to 480 VAC offers wide-ranging advantages for their flexible use around the globe. At the same time, the performance of all 230 VAC versions has been increased so significantly that they now reach performance ranges that were primarily reserved for the previous 415 VAC brakes. Franz Eisele illustrates what this means in practical terms with an example: "The clamping forces of the 230 VAC brakes of the third size EH028/EV028 have thus been increased from 7,000 N to 10,000 N." With regard to the supply voltage, the series have also been closed so that all EH/EV brakes from RINGSPANN are now suitable for operation on 220-240 VAC and 380-480 VAC.

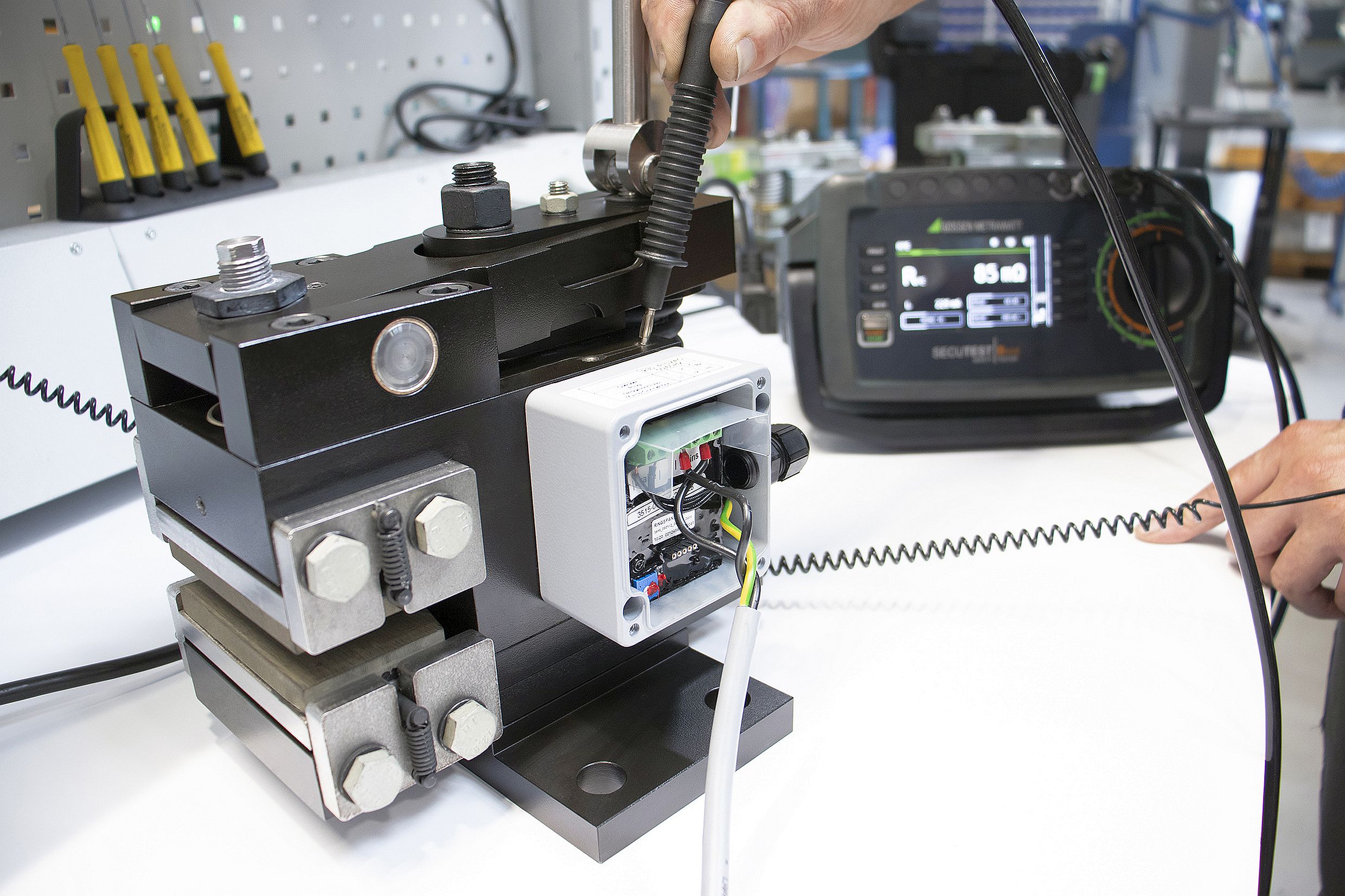

The voltage and performance expansion of the EV/EH series is highly relevant, especially in conjunction with the CSA/UL certification of RINGSPANN’s electromagnetic disc brakes. Export-oriented manufacturers of drives, machines and systems who operate on the world market and also serve customers in the USA and Canada particularly stand to benefit from this. Both the uncomplicated connection and operation of the brakes, and the simple, fast market access through the UL (Underwriters Laboratories) and CSA (Canadian Standards Association) test seals are proving themselves to be persuasive advantages in international competition.

Intelligent and corrosion-protected

RINGSPANN is also offering users additional perspectives for the practical use of the disc brakes with the other options newly added to the EV/EH series range. While it was already possible to optimise the control and regulation of the brakes with three inductive sensors for the statuses of brake released, brake activated and wear state, they can now also be (retroactively) equipped with a mechanical emergency release and extended corrosion protection. "The variants with increased corrosion protection in particular are suitable for use in food technology and chemical technology, as well as for applications in offshore and marine technology," notes brake specialist Franz Eisele.

The typical areas of application for the RINGSPANN’s EV/EH electric brakes include the turbine, fan and ventilator industries and winch technology. The series currently covers clamping forces from 3,200 N to 24,000 N and braking torques from 100 Nm to 3,400 Nm across all 16 types and variants, whereby these figures apply to use on standard brake discs. "The clamping force is the force generated directly by the brake on the brake disc; the braking torque, on the other hand, is the moment that acts on the disc or shaft at the end," explains Franz Eisele.

By the way: During the entire stopping phase, the disc brakes of the EV/EH series from RINGSPANN require very little power; just 10 watts for the small sizes. This is an excellent figure - even in international comparison - which enables the realisation of energy-efficient drive solutions. ms

Wide-ranging brake portfolio

RINGSPANN’s brakes are deployed as stopping, control and holding systems everywhere in industry: In the turbine, fan and ventilator industry, in machine tool construction, in winch and winding technology, in the wind power industry, in general drive technology, in conveyor and crane systems, lifting and handling systems, mining and construction machinery, in marine, recycling and metallurgical technology and many other areas. RINGSPANN provides customers with a technologically almost comprehensive range of brakes, which comprise all important functional and design types. In order to make it easier for designers and engineers to select the right brake, RINGSPANN has also developed a calculation tool that can be used free of charge in the company’s online shop at www.ringspann.de. It enables you to determine braking torques (clamping forces) and braking forces. It allows you for example to calculate the braking of rotating masses (e.g. shafts), carriages, cable winches and conveyor belts.